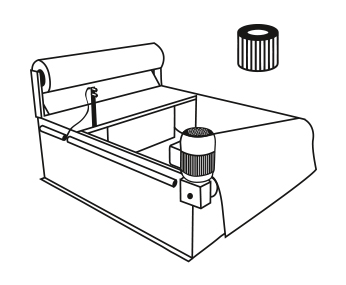

Belt filter / compact filter

As fleece or endless belt filters, belt filters can supply individual machines or machine groups.

For versatile use in a wide variety of designs, our filters are robust helpers in production.

The customer’s wishes are the measure of all things at POLO Filter-Technik, which means:

These aspects result in individual and customer-oriented solutions.

Belt filter / compact filter

As fleece or endless belt filters, belt filters can supply individual machines or machine groups.

For versatile use in a wide variety of designs, our filters are robust helpers in production.

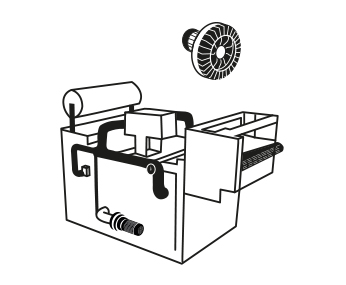

Vacuum filter / suction belt filter

Filters that are operated with vacuum, filter large quantities of liquids on a small surface area, can be used flexibly, are available in fleece or endless belt design and in different sizes and materials.

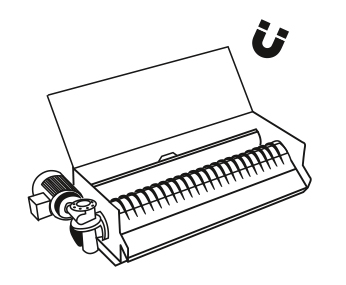

Magnetic filter

With magnets, amazing filtration results are achieved without any filter aids. They can be used as single filters or pre-filters.

These are available in different sizes and material finishes.

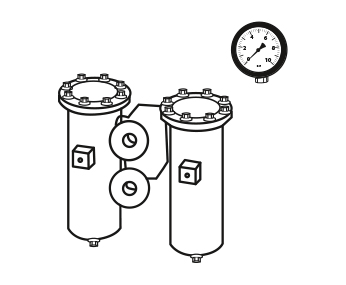

Ultrafine filter /

pressure filter

Used in hydraulics or as “police filters”.

Depending on the filter inserts

used, enormous fineness can be achieved.

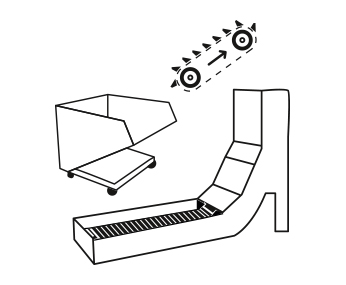

Chip conveyor / chip trolley

The conveyors automatically discharge coarse chips, in different designs depending on the type of chip. Chip trolleys are used to transport discharged chips to the collection point.

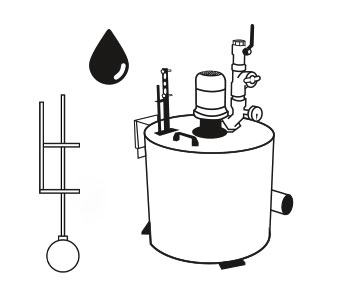

Lifting stations / surface skimmers / float switches

These peripheral devices monitor the fill level, bring contaminated coolant to the filter and/or remove floating particles out of the clean tank.

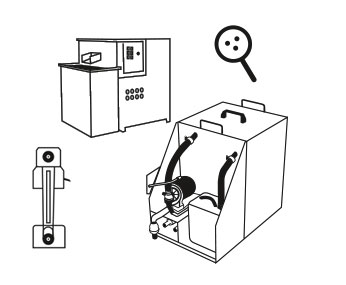

Cooling lubricant care devices / oil skimmers

Even after good filtration, the liquid needs further treatment. Foreign oils and/or ultra-fine particles can be removed in different ways. This improves the service life of the coolant and the quality of the products.

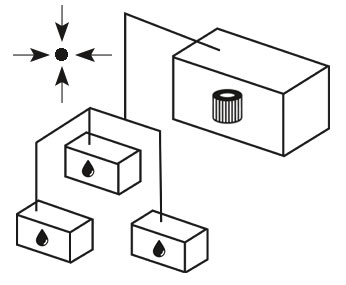

Central systems

POLO central systems supply several machines or entire production lines with cleaned coolant, regardless of whether they are used as a main plant or a sub-plant.

With a central system, resources can be saved sustainably.

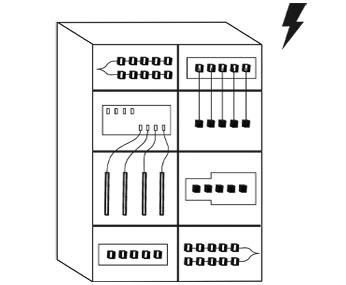

Control engineering

Our systems are electrically controlled, of course.

A wide variety of controls and visualisations can be configured. Energy-saving, frequency-controlled pumps/motors can be used.

Challenge us.