A professional in every size

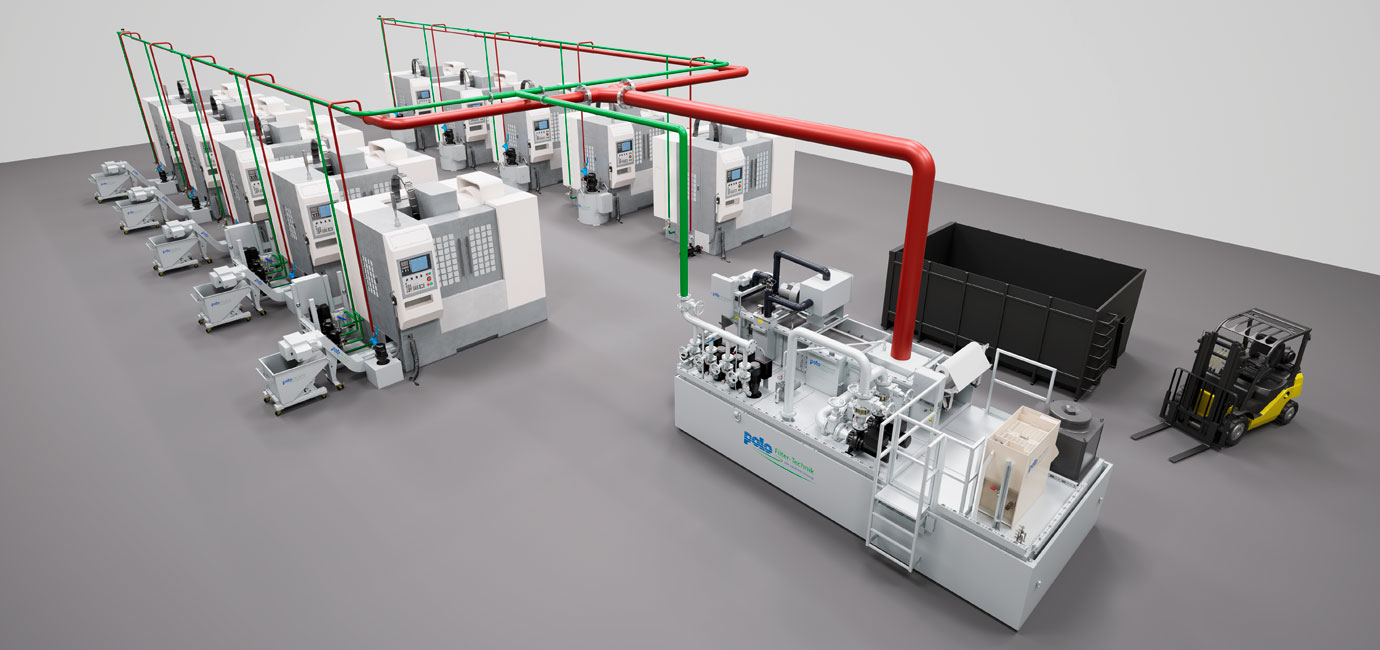

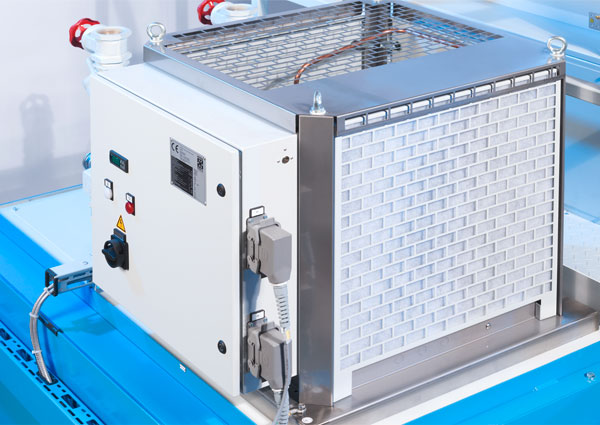

POLO central systems are ideally suited for cleaning larger volume flows of cooling lubricants. Each system is individually designed to meet the specific needs and spatial conditions on site. POLO’s many years of experience guarantee a high quality standard with continuous operational reliability of your production.

As a general contractor (GC), POLO offers individual components through to turnkey central systems, including piping networks.

By professionals, for professionals, with professionals